Progress isn’t something that happens overnight. It’s a steady march towards the future. When done right, automation has proven to deliver real benefits, including the following:

Increased savings and productivity

Faster service: Processing time reduced from days to minutes

Increased flexibility and scalability: Ability to operate 24/7 and scale up or down with demand

Improved quality: From spot-checking to 100 percent quality control with greater traceability

New insights to predict and drive performance

However, success is far from guaranteed. We all know of projects that have failed to deliver the promised impact or were much harder to implement than expected.

Here are the five most important practices that lead to success in automation:

Understand the opportunity and move early: Start taking advantage of automation by assessing the opportunity, identifying the high-impact use cases, and build a solid framework. Build a cost model to ensure a reasonable payback period.

Balance quick tactical wins with a long-term vision: Identify quick wins with the highest potential. But have a long-term vision for comprehensive transformation. An example is to initially automate a portion of an assembly or test process instead of the whole solution. This approach will improve your process and allow you to make money while developing the entire solution.

Look end-to-end and redefine processes. Consider the previous process and the post-processes to ensure connectivity and create a smooth flow. An example is creating common carrying fixturing for partial assemblies between each process.

Create a culture of collecting and analyzing data to inform decisions. Consciously and deliberating focus on continuous improvement. For example, create a series of metrics representing a successful product creation.

Create an automation-friendly design. An example is something that has hooks for automation, like pick points, visual alignment identifiers, and progressive alignment features.

Design for Automation

What's easy for a human assembler can be difficult or impossible for a robot, and vice versa. To ensure success with robotic assembly, an old product designed for human assembly may need to be re-designed for robot assembly.

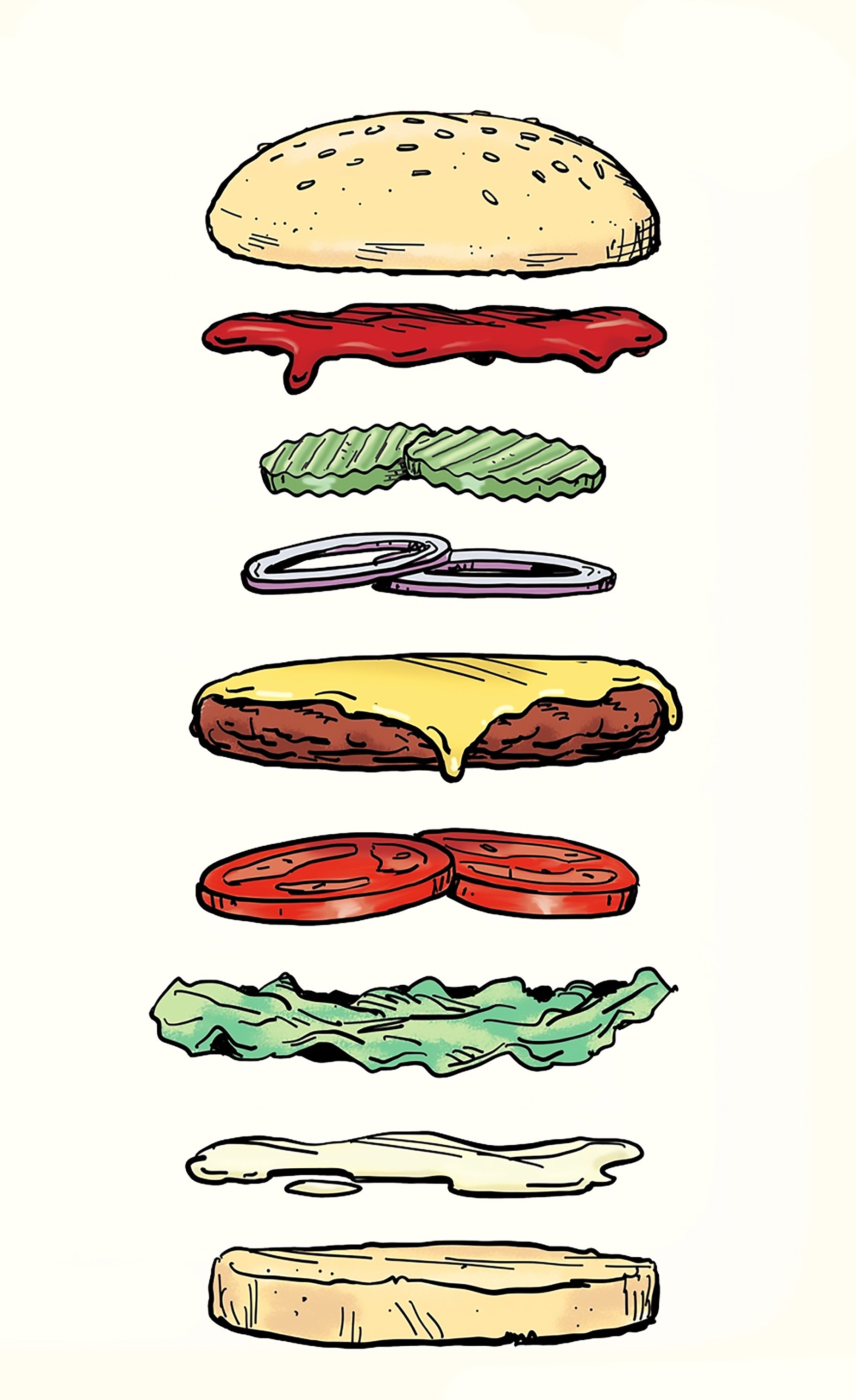

An example is adding alignment features that make two parts fit together better when a clumsy robot is assembling. In addition, parts should be designed as self-aligning snap together versus screws or welding. Finally, the assembly should be done, starting with the bottom part and stacking other components on top.

Although a human can quickly turn an assembly over, it is much harder for a robot. Therefore, products should be designed to assemble in layers from the bottom up. This way, the robot has an easier time visualizing and placing components.

Robotic grippers are not as nimble as human hands, so the design must ensure that the robot can manipulate the parts. In general, flexible parts are difficult for robots. Also, care must be taken for cosmetic surfaces or fragile materials that the grippers could damage. For example, a part with a top cosmetic surface should be picked up with a soft element such as a vacuum suction cup or picked up from the sides with a parallel gripper to avoid any contact with the cosmetic surface.

Robotic assembly may be affected by tolerances and inconsistent parts. Also, how the parts are fed to the robot must be planned. Planning the feeding method will ensure that assembly will be less expensive in the end. Common feeding methods include random parts on a conveyor or fixtured parts in a track or tray.

Design for robotic assembly

At Fusion Design, we address the issues related to robotic assembly early in the design process. We have years of experience developing end-to-end processes and delivering successful automation.

KEYWORDS: design for automation, design for robotic assembly